Services

Our Service department is undoubtedly the most important part of our business. Because our commitment to you doesn’t stop once we’ve installed a compressed air system and driven away.

Regular maintenance will ensure that the SCR air compressors that we supply remain operating reliably and at peak efficiency.

Our engineers are regularly trained to the highest standards. This includes full training on all our compressors product range and ancillary equipment.

We also service all popular compressor manufacturers, including Atlas Copco, Champion, Kaeser, Sullair, Ingersoll Rand, Senator, CP-Chicago Pneumatic, Compair, Gardner Denver, Hertz, CAPS, Renner, Pilot, Peerless, Infinity, Kaishan, Pulford, Ceccato, Airmac, Boge, and others.

INSTALLATIONS

Our qualified and experienced pipework and installation teams specialise in all aspects of compressed air piping. We install compressor rooms to complete factory ring mains and can cover all your compressed air requirements.

Westair Pneumatic Systems has partnered up with Airpipe® to deliver an engineered aluminium compressed air piping system that is competitively priced and vigorously tested for safe operation in all compressed air applications.

The Airpipe® system is very simple, easy to install and modify, as no specialised tools are required. To ensure optimum performance, Airpipe® piping system is of high quality, corrosion free, UV resistant and is compliant with Australian Standards.

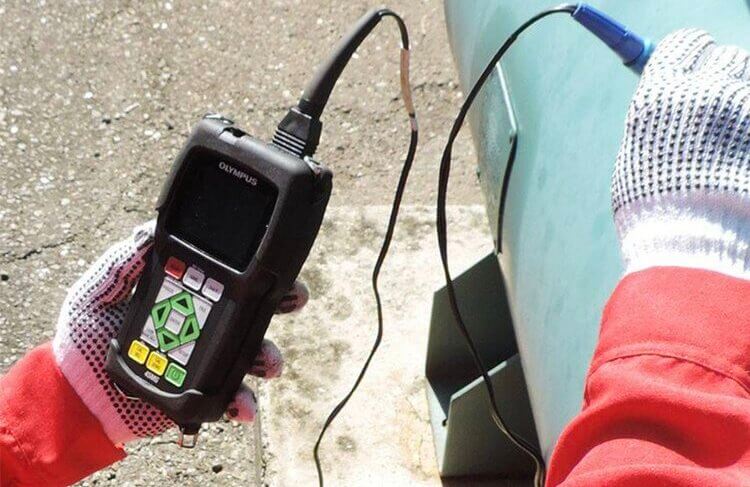

PRESSURE VESSEL INSPECTIONS

Westair Pneumatic Systems are fully equipped to perform on site pressure vessel inspections. State and federal legislation requires the regular in-service inspection of pressure vessels in accordance with AS/NZS3788 to ensure continued safe use.

Every 2 years your air receiver will need to inspected with the safety valve tested or replaced.We will arrange a time that suits you for one or our experienced technicians to come and inspect your air receiver.On completion of job, you will be supplied a detailed pressure vessel inspection report in compliance with AS/NZS3788.

PARTS

As the sole distributor of SCR in Australia, it is our duty to stock a full range of spare parts for all our SCR compressors. In the unlikely event of any issues, we will have the parts on the shelf ready to go.

Parts we stock include minor and full service kits, oil, preventative maintenance kits, Controllers, displays, inverters, solenoids, sensors, contactors, belts, hoses and plenty more.

Parts we stock include minor and full service kits, oil, preventative maintenance kits, Controllers, displays, inverters, solenoids, sensors, contactors, belts, hoses and plenty more.

AIR AUDIT

SCADAR’s sensor and data analysis tools can be applied to any form of compressed air product or system, regardless of its size, brand or age. Its comprehensive suite of compressed air auditing products, which have been developed by CMC – the global experts in compressed air control, performance and monitoring solutions – Westair measures ALL critical elements of a compressed air system, from standalone units to entire systems.

SCADAR’s measurements include volts, amps, pressure, temperature, moisture and flow, which enable us to provide an accurate report to help you size the correct compressors, provide energy savings and also reducing your carbon foot print.

AIR LEAK TESTING

Reduce your energy costs by fixing compressed air leaks and increase your profitability and sustainability. Westair have invested in CS ultrasound leak detectors which are of the highest quality and most technically advanced.

After the leak survey is complete, Westair can provide a detailed Leak Report with pictures highlighting how much it is costing your company each year. We will then arrange a time to fix the leaks in your system to make it as efficient as possible and save you money and reduce your carbon foot print.

1300 183 355

1300 183 355  sales@westairps.com

sales@westairps.com