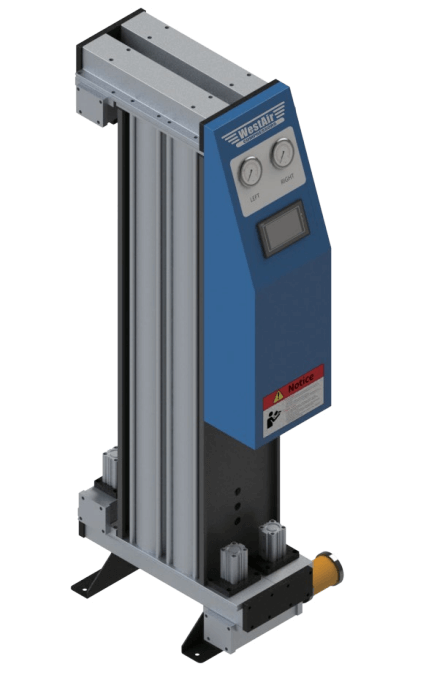

Desiccant Series

The WMD dryer consists of extruded aluminium columns which are filled with high performance desiccant which dries the compressed air passing through it. The saturated compressed air will be directed via the inlet switching valve into one of the columns, which is filled with high performance desiccant. Moisture in the compressed air will be adsorbed by the desiccant, which results in dry compressed air exiting from the column through the upper valve at the dryer outlet into the production supply (Bottom to Top).

While one column is removing the moisture from the compressed air (adsorption), the other column is regenerating the saturated desiccant bed simultaneously via the Pressure Swing Adsorption (PSA) method. A small stream of dried air from drying column will be directed into regeneration column through the orifice and exit from regeneration column through the exhaust valve and exhaust silencer (Top to Bottom). The expansion from operating pressure to atmospheric pressure will allow the small stream of dried air to remove the moisture that is adsorbed by the desiccant. Pressurisation will take place after regenerating column is completely regenerated. The dryer cycle will then switch over and repeat the whole cycle. The WMD is based upon well proven concepts which embody true innovation and excellent value for money, simple design and is technically superior to other methods.

KEY FEATURES

High Quality Air Clean

Dry compressed air supply in accordance with the ISO8573-1

Dew Point Performance

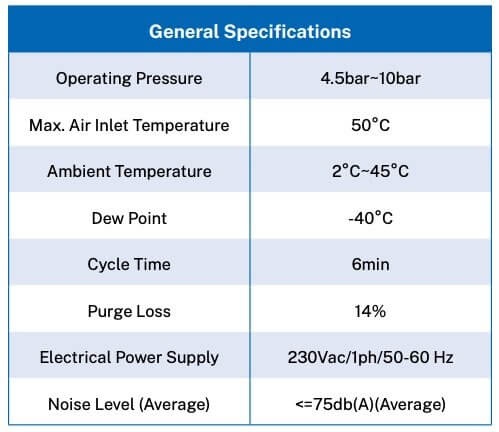

Stable dew point performance down to -40°C (ISO8573.1 Class 2) and -70°C (ISO8573.1 Class 1) option

Reliability

Only field proven and tested components in use • Smart Touch Screen Control Equipped with an easy to use touch screen control panel as standard or have the option for a Siemens PLC touch screen.

Energy Efficient

With Dew Point Operation System (DPOS) optional, WMD dryer provide maximum energy saving

Simplified Maintenance

WMD dryer have been designed with the end user in mind for easy access and maintenance

Space Saving

With the aluminium extruded column replacing the traditional vessel design, it will only require half the space

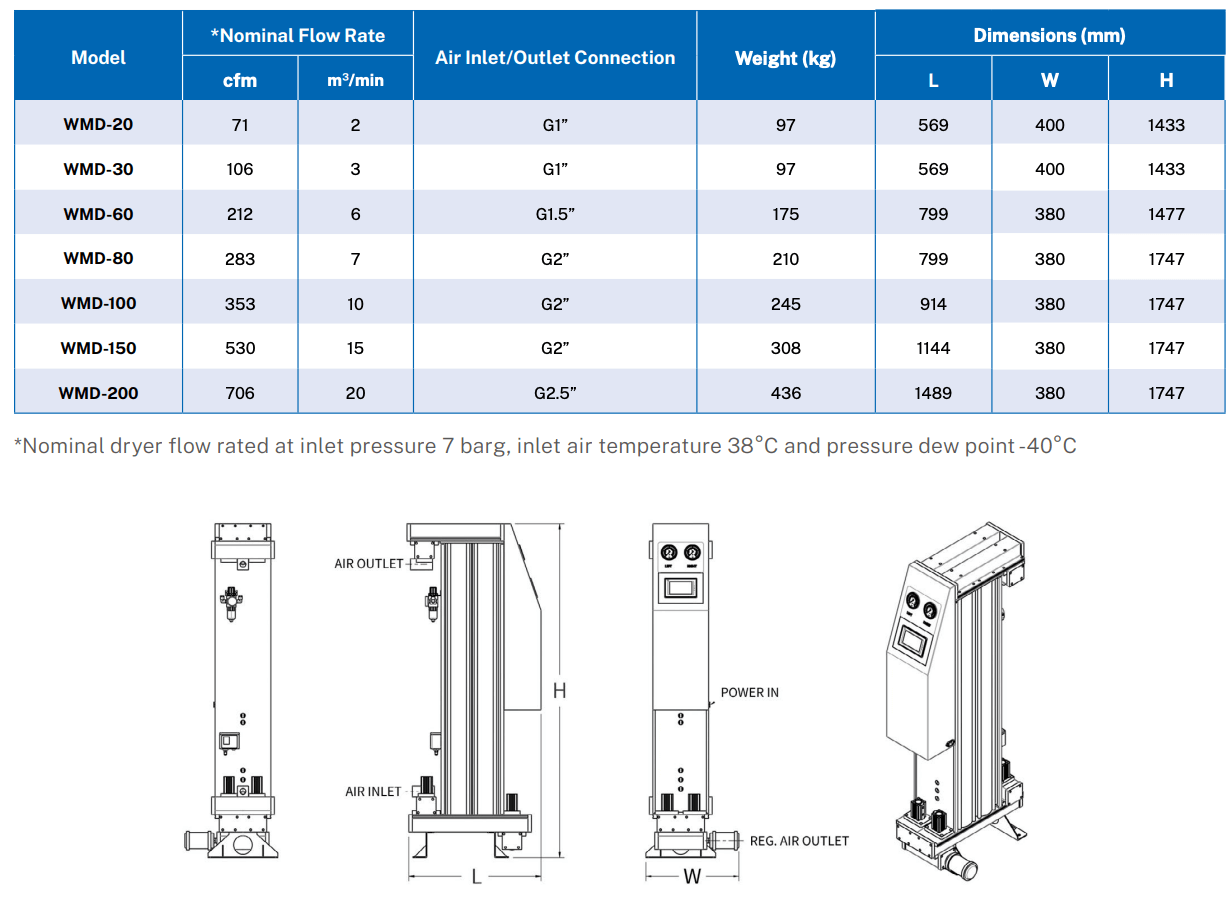

Technical Specifications

Product Selection of WMD Series

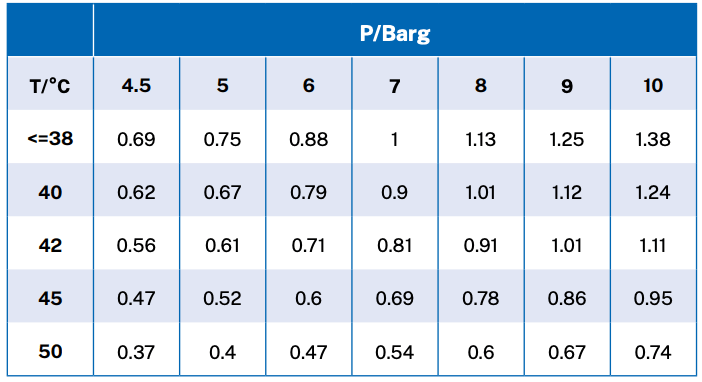

Correction factor for inlet pressure(P) and inlet temperature(T)

Actual flow rate = Air flow at nominal condition x Correction factor

For higher pressure, flow and lower dew point (-70°C), please consult Westair Pneumatic Systems

1300 183 355

1300 183 355  sales@westairps.com

sales@westairps.com