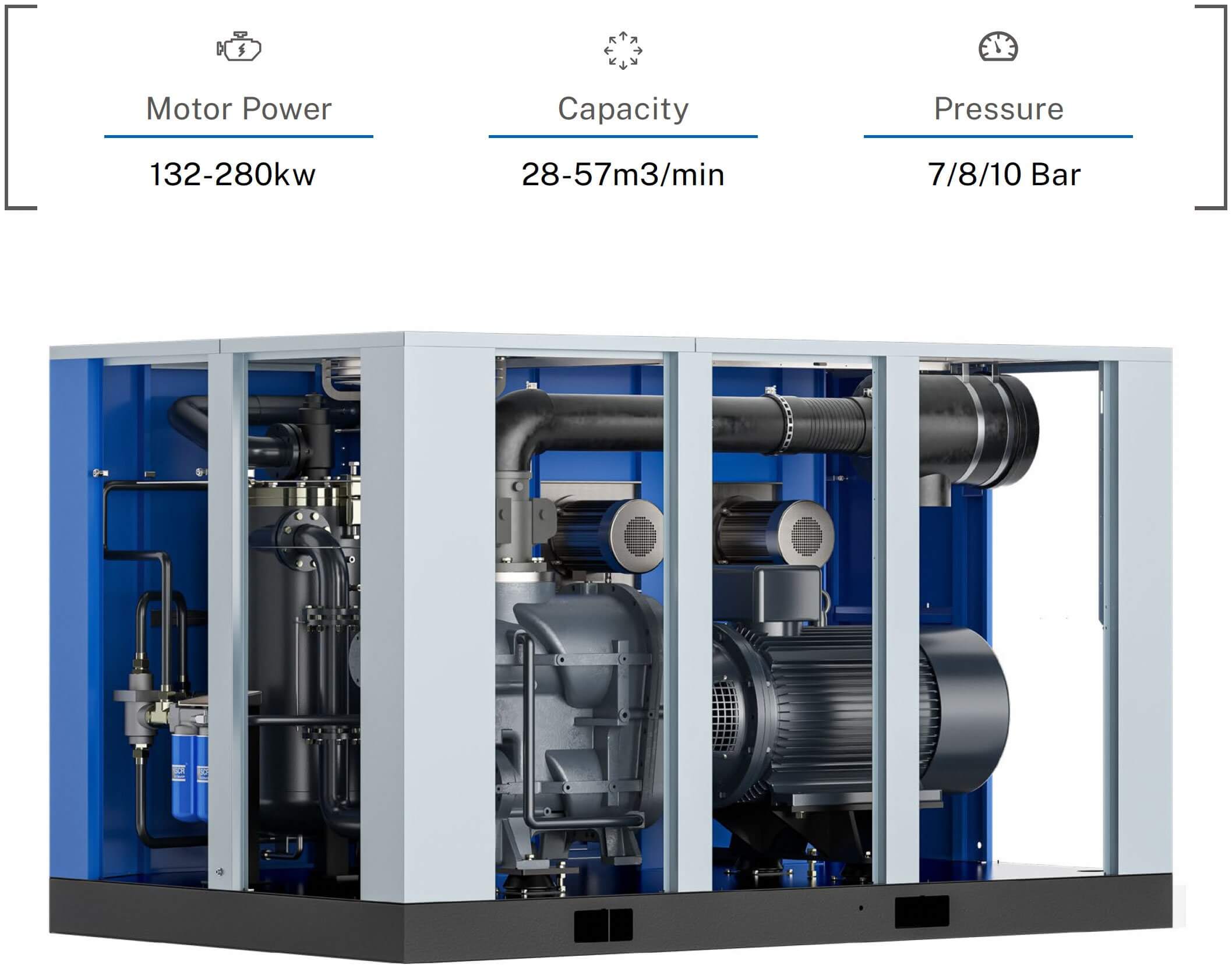

HV Series

2 Stage Variable Speed Drive (132kW-280kW)

ULTIMATE ENERGY EFFICIENT 2 STAGE COMPRESSOR

The H/HV 2 stage series range pushes the boundaries of compressed air efficiency. The latest generation of the H/HV series is class leading and has low energy consumption, resulting in reduced running costs and lower CO2 emissions. Like all SCR compressors, it is intuitive, maintenance-friendly and exceptionally versatile with an environmentally responsible design.

FEATURES:

- Energy-saving variable speed control (HV series)

- Super premium efficiency motor

- Fixed speed H series range available

- 30-100% variable speed range

- Oversized innovative cooling system

- Suitable for use up to 50°C+ ambient

INOVANCE VARIABLE SPEED DRIVE (HV SERIES)

SCR VSD compressors in Australia have used Inovance VSDs for over ten years. Their innovative energy-saving features and proven reliability in some of the country’s toughest environments make Inovance the perfect choice for the HV series.

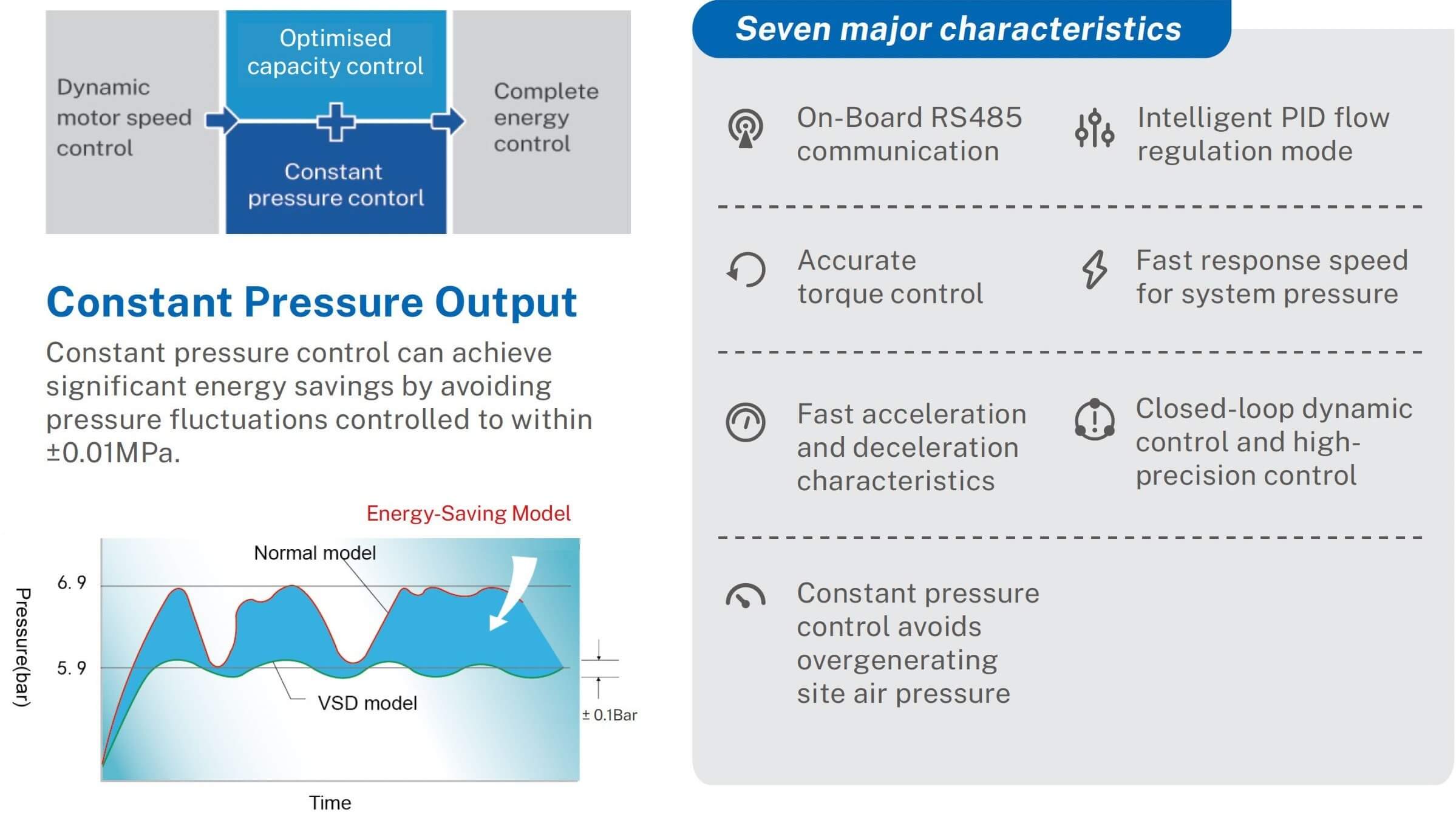

DOUBLE VSD ENERGY-SAVING TECHNOLOGY

MAIN MOTOR INVERTER

DESIGN CONTROL

Stable constant pressure

The SCR HV compressor’s wide operating variable speed range ensures stable constant pressure control and reduces power consumption. SCR’s exclusive inverter and energy-saving logic control can optimise energy savings regardless of the load condition. They can react to pressure changes quickly, maintaining pressure fluctuation at ±0.01 MPa.

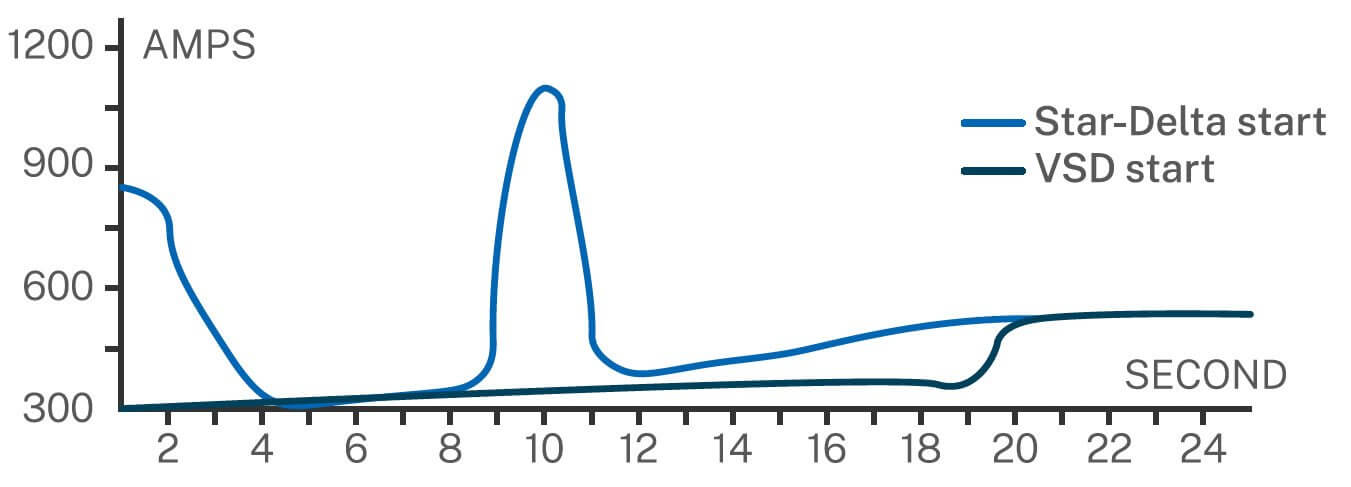

PURE SOFT-START SYSTEM AS STANDARD

Soft Start System Reduces Electric Current During Start-Up

The SCR HV series adopts a soft start system for its start-up. Traditional motor starters, such as direct online and star-delta starters, burden the power supply due to the high peak start-up current, typically 3.5 times their full load current (FLC). With a variable speed soft-start system, the starting current never exceeds the rated value.

SUPER PREMIUM EFFICIENCY MAIN MOTOR

- Standard TEFC motor

- IE3 motor efficiency

- F insulation grade

- IP 55 protection grade

- SKF bearings

- Automatic grease replacement (option)

- Bearing temp monitoring (option)

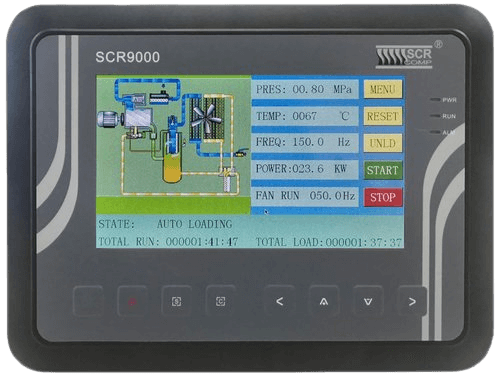

STATE-OF-THE-ART TOUCH CONTROLLER

- Seven-inch full-colour LCD touch screen

- Real-time operation/maintenance

- Alarm information

- Graphical flow diagram

- Operation record/chart display

- Service alarm

- On board RS485 interface

- Modbus RTU communication

- Energy-saving logic

- Pressure/temperature/overload/overcurrent/ phase loss/unbalance protection

- Pre-alarm system to avoid sudden failure

- Remote monitoring capability

- Programmable start/stop and pressure schedules

- Master/slave operation (Maximum 16 compressors)

- Stop/start remote

- Fault history

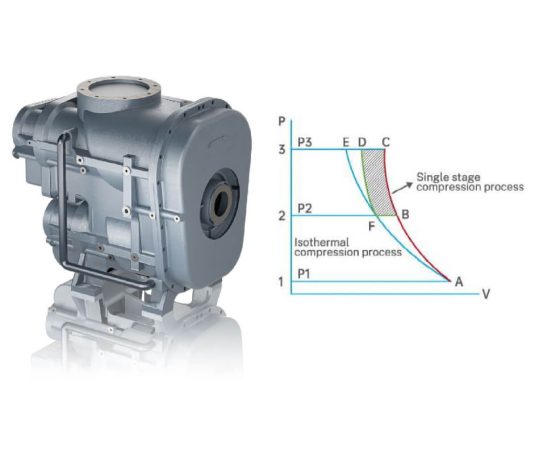

HOW THE TWO-STAGE AIRENDS WORK

The SCR Two Stage essentially has two airends, one large low pressure airend and one smaller high pressure airend, both integrated within the same airend “block”. Atmospheric air enters the low pressure airend and is pressurised to around 50% of the final pressure. The pressurised air then enters the second ‘high pressure boosting airend’ where air is compressed to the final pressure. The lower compression ratios in each airend offer superior volumetric efficiency, lower vibration, lower noise, higher reliability and lower heat generation on compression. As a result of these mechanical efficiencies, the two-stage airend can produce more air, which in turn can lead to a lower kW compressor being used to supply your air requirements. With power costs being the greatest cost factor when buying a compressor, this can lead to a significant saving over the life of your air compressor. The standard airend found in most compressors must compress the atmospheric air up to the final discharge pressure in a single-stage and requires more energy and generates more heat.

TWO-STAGE FEATURES

- The rotors are meshed and sealed with an oil film belt to reduce wear

- R&D in Japan

- Reduces the compression ratio with each compression

- Reduce energy consumption

- Low differential pressures

- Improved volumetric efficiency

- Low thermal load

- Longer life span of bearing

WHY TWO-STAGE COMPRESSION SAVES MORE ENERGY

Isothermal compression saves the most energy

- AFE31 is area of isothermal compression

- ABC31 is area of standard compression

- AB, BF, FD, 31 is area of two stage compression

- Two stage compression saving area is BCDF comparison with standard compression

After first grade compression, the volume of compressed air becomes smaller, then the second compression uses smaller roto, which reduces the compression leakage.

This reduces compression ratio which reduces leakage.

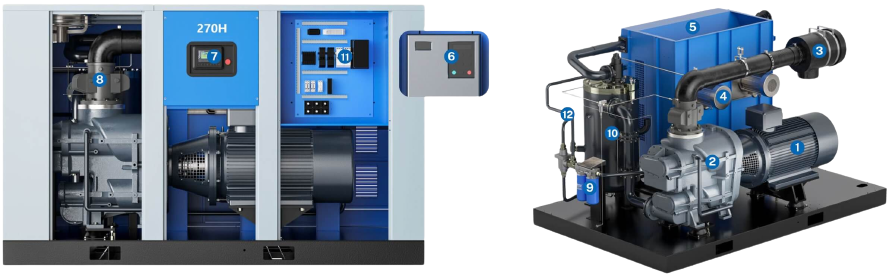

SCR H/HV2 STAGE SERIES KEY FEATURES

1. PREMIUM EFFICIENCY MOTOR

- Exceed IE3 standards

- Smooth Reliable operation

- SKF bearings

- Long service life

2. 2 STAGE COMPRESSOR AIREND

- Latest patented profile

- Optimum compression and bearing design leads to a typical service life of 100,000 hours

- Low noise, low vibration and reliable

- High compression ratio

- No air slippage leads to very high efficiency

3. INLET FILTER

- Nanoscale heavy duty

- Filtration accuracy up to 99.9%

- Dust particles below 0.3 micron

- Pressure drop indicator

- Extends the service life of the lubricating oil and oil filter

4. CENTRIFUGAL COOLING FAN

- Compact

- Low noise level

- High capacity for optimised cooling

- Low power consumption

5. CLASSIC COOLER DESIGN

- Separate oil/air cooler

- Easy access for maintenance

- Anti-corrosion painted surface

- 30% oversized cooler design

6. INNOVATIVE INOVANCE INVERTER (HV SERIES)

- CE/UL/CUL certification

- Wide voltage design

- Meets C3 and C3 EMC requirements

- Built-in DC reactor

- Independent cooling air duct design

- Robust enclosure for trouble-free operation even in the harshest conditions

7. SCR 9000 TOUCH CONTROLLER

- Seven-inch full-colour touch screen

- Real-time operation/maintenance/alarm information

- Full graphical flow diagram

- Operation record/chart display

- Weekly and daily scheduling, service history and planning

- RS485 interface, MODBUS RTU Protocol+

8. INLET VALVE

- Optimises the inlet flow of the airend

- No blowdown losses

- Full aluminium maintenance-free design

- High vacuum degree: 700mmhg

- Large suction area

- Low load energy consumption in unloaded operation

- Fluoro rubber for improved valve seal

9. OIL FILTER

- High-efficiency oil filter removes contaminants from the oil

- Oil particles can be controlled at 0.1 micron

- Ensures a smooth and well-lubricated oil system

10. GAS TANK & BUILT-IN SEPARATION SYSTEM

- AS1210 designed and certified

- Oversized air and oil tank improves the cyclone effect maximising the separation process

- The high-efficiency oil separator ensures that the oil carryover is less than 3ppm

- Systems pressure loss: less than 0.02mpa

- The rotating oil tank lid makes maintenance convenient and straightforward, reducing maintenance downtime

11. ELECTRICAL CONTROL CABINET

Siemens core electrical components further enhance reliability

12. ALL STEEL INTERNAL PIPE SYSTEM

- All steel internal pipework and compression joints prevent the leakage and premature ageing often seen with flexible pipes

- Reduced air flow friction

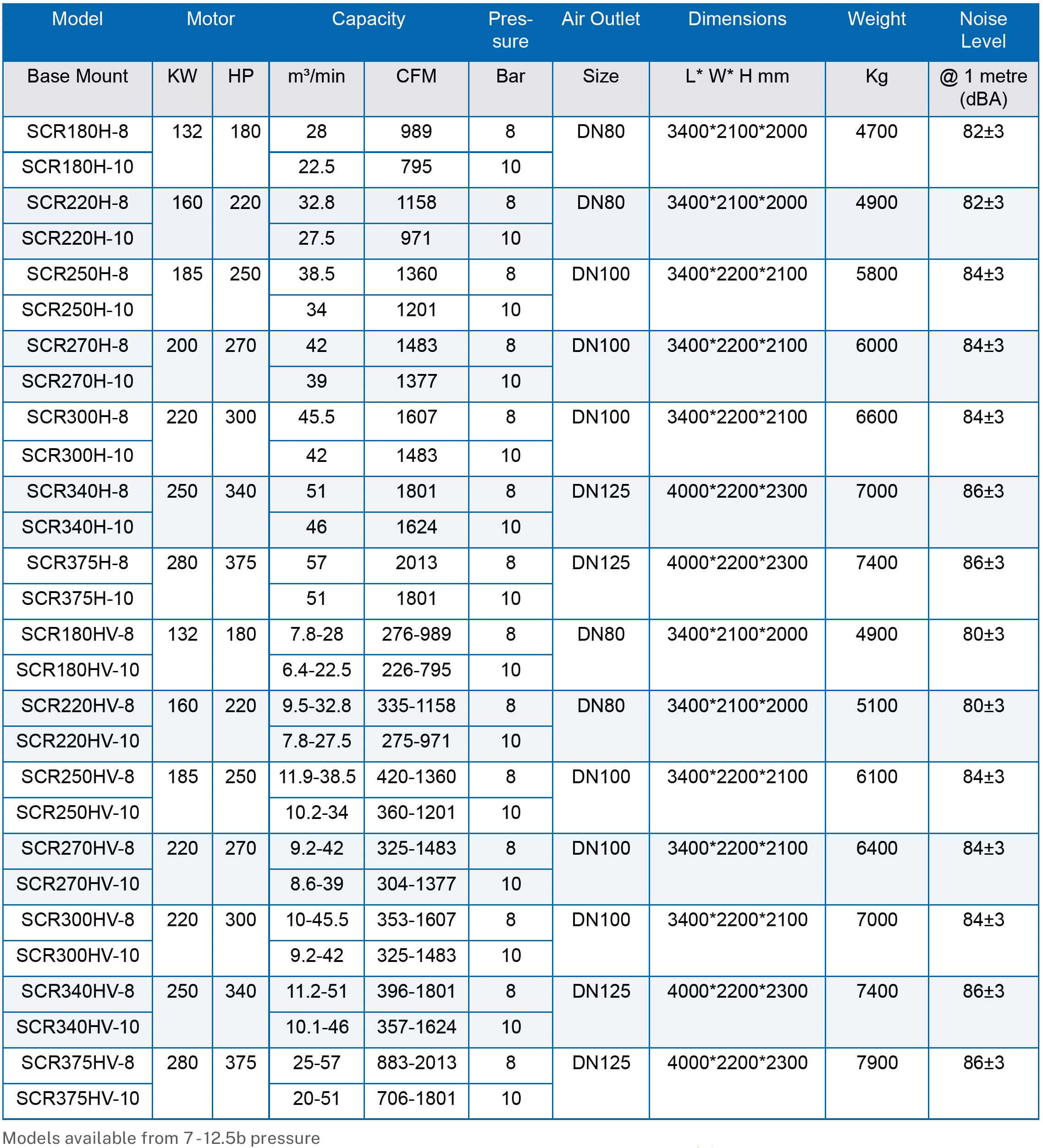

SPECIFICATION

Warranty

Standard 2-year warranty – covers the complete compressor (terms and conditions apply)

1300 183 355

1300 183 355  sales@westairps.com.au

sales@westairps.com.au