EPM Series

Oil Free Rotary Screw Compressor (37kW-280kW)

ULTIMATE ENERGY EFFICIENT INVERTER MODEL

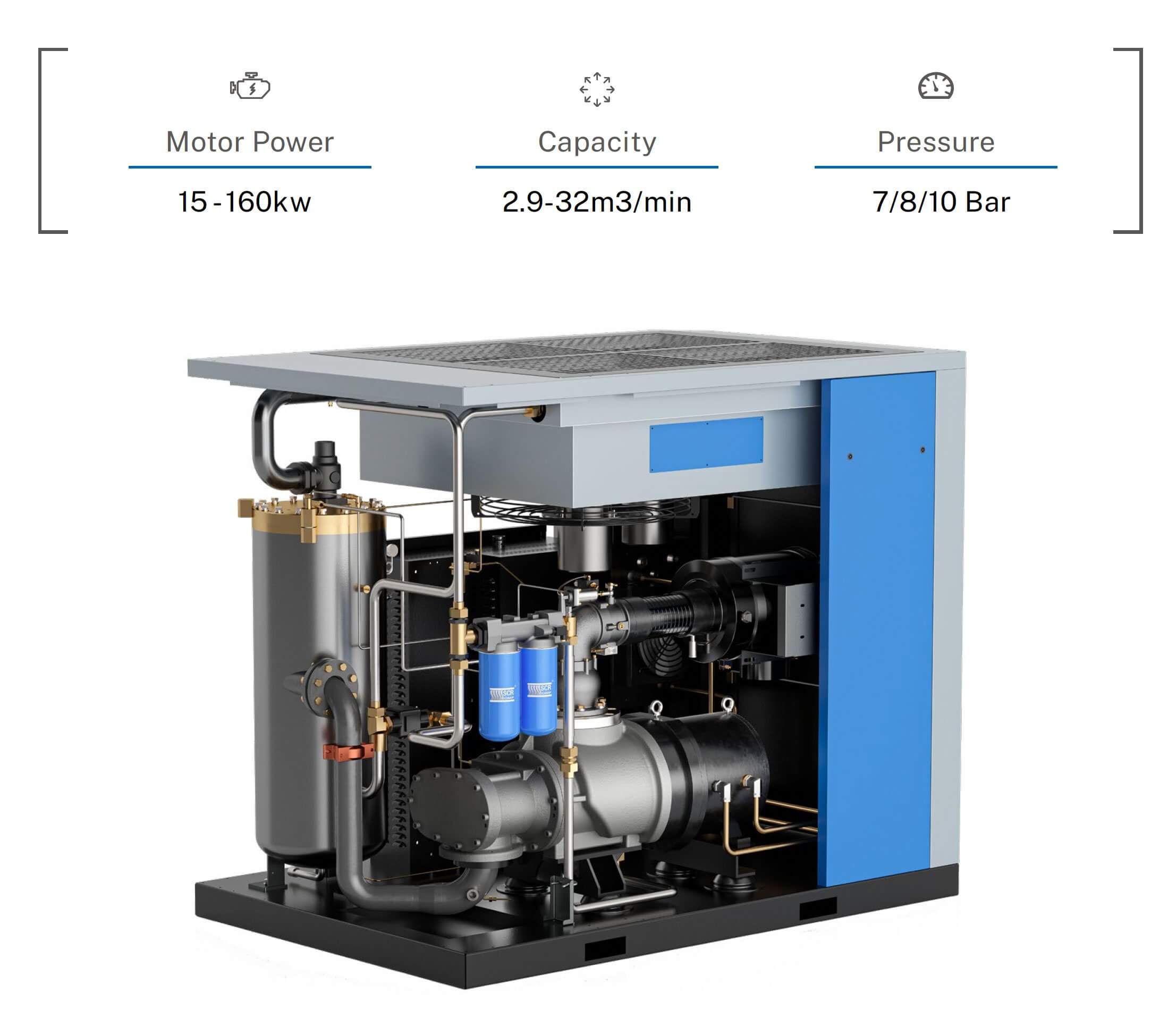

The SCR EPM (15–45kw) and EPM2 (55-160kw) range pushes the boundaries of compressed air efficiency. The latest generation of the EPM2 series is class leading and has low energy consumption, resulting in reduced running costs and lower CO2 emissions. Like all SCR compressors, it is intuitive, maintenance friendly and exceptionally versatile with an environmentally responsible design.

FEATURES:

- Energy-saving variable speed control

- Super premium efficiency PM motor (IE4 equivalent)

- Morse connection design for motor and airend

- 30-100% variable speed range

- Oversized innovative cooling system

- Suitable for use up to 50°C ambient

INOVANCE VARIABLE SPEED DRIVE (VSD)

SCR VSD compressors in Australia have used Inovance VSDs for over ten years. Their innovative energy-saving features and proven reliability in some of the country’s toughest environments make Inovance the perfect choice for the EPM series.

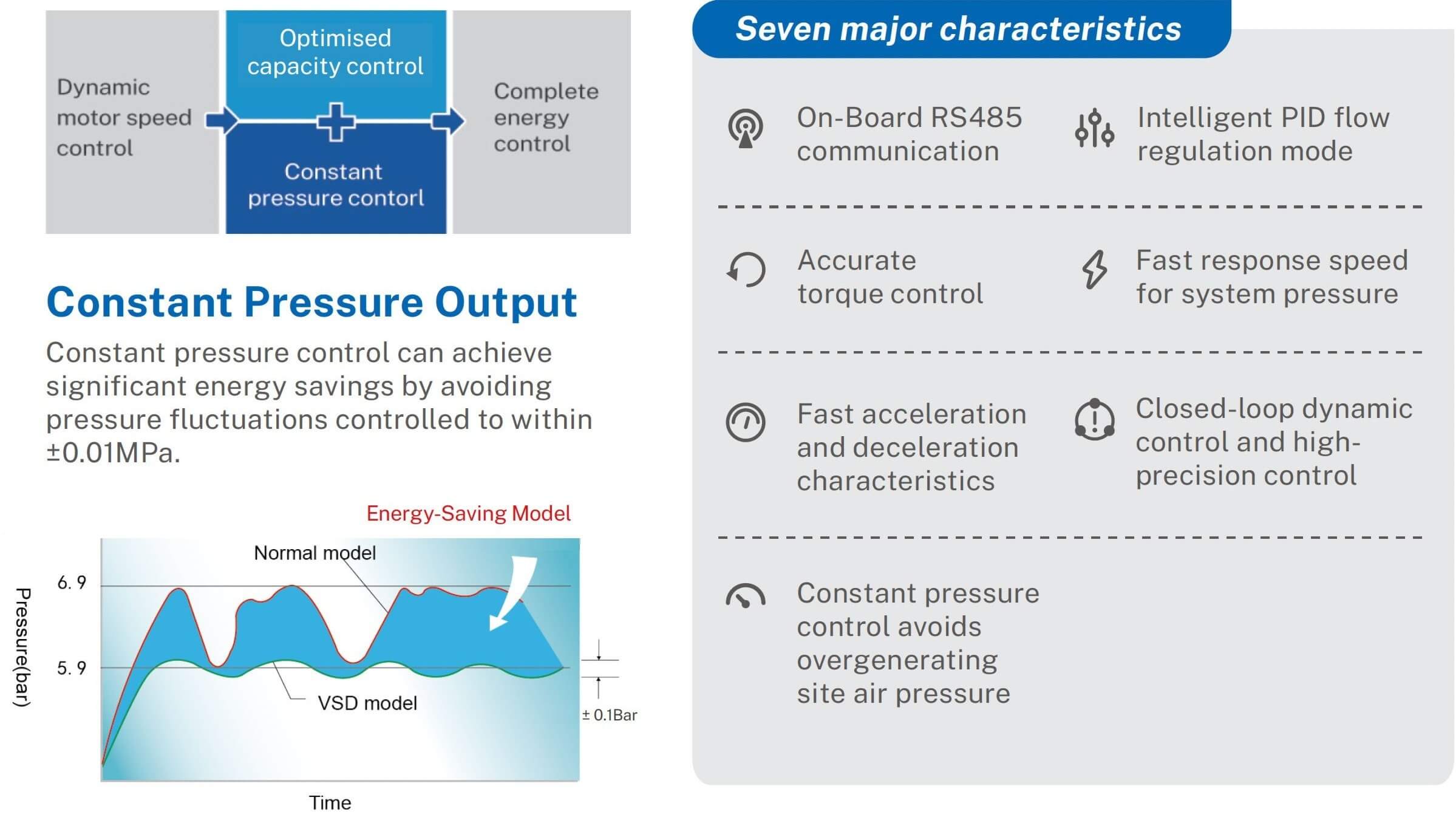

DOUBLE VSD ENERGY-SAVING TECHNOLOGY

MAIN MOTOR INVERTER

DESIGN CONTROL

Stable constant pressure

The SCR EPM compressor’s wide operating variable speed range ensures stable constant pressure control and reduces power consumption. SCR’s exclusive inverter and energy-saving logic control can optimise energy savings regardless of the load condition. They can react to pressure changes quickly, maintaining pressure fluctuation at ±0.01 MPa.

FAN MOTOR INVERTER DESIGN CONTROL

Stable constant temperature

Setting a constant temperature ensures the best lubrication performance, avoiding high-temperature trips.

PURE SOFT-START SYSTEM AS STANDARD

Soft Start System Reduces Electric Current During Start-Up

The SCR EPM/EPM2 series adopts a soft start system for its start-up. Traditional motor starters, such as direct online and star-delta starters, burden the power supply due to the high peak start-up current, typically 3.5 times their full load current (FLC). With a variable speed soft-start system, the starting current never exceeds the rated value.

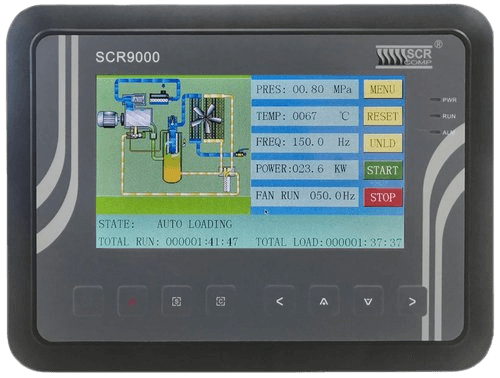

STATE-OF-THE-ART TOUCH CONTROLLER

- Seven-inch full-colour LCD touch screen

- Real-time operation/maintenance

- Alarm information

- Graphical flow diagram

- Operation record/chart display

- Service alarm

- On board RS485 interface

- Modbus RTU communication

- Energy-saving logic

- Pressure/temperature/overload/overcurrent/ phase loss/unbalance protection

- Pre-alarm system to avoid sudden failure

- Remote monitoring capability

- Programmable start/stop and pressure schedules

- Master/slave operation (Maximum 16 compressors)

- Stop/start remote

- Fault history

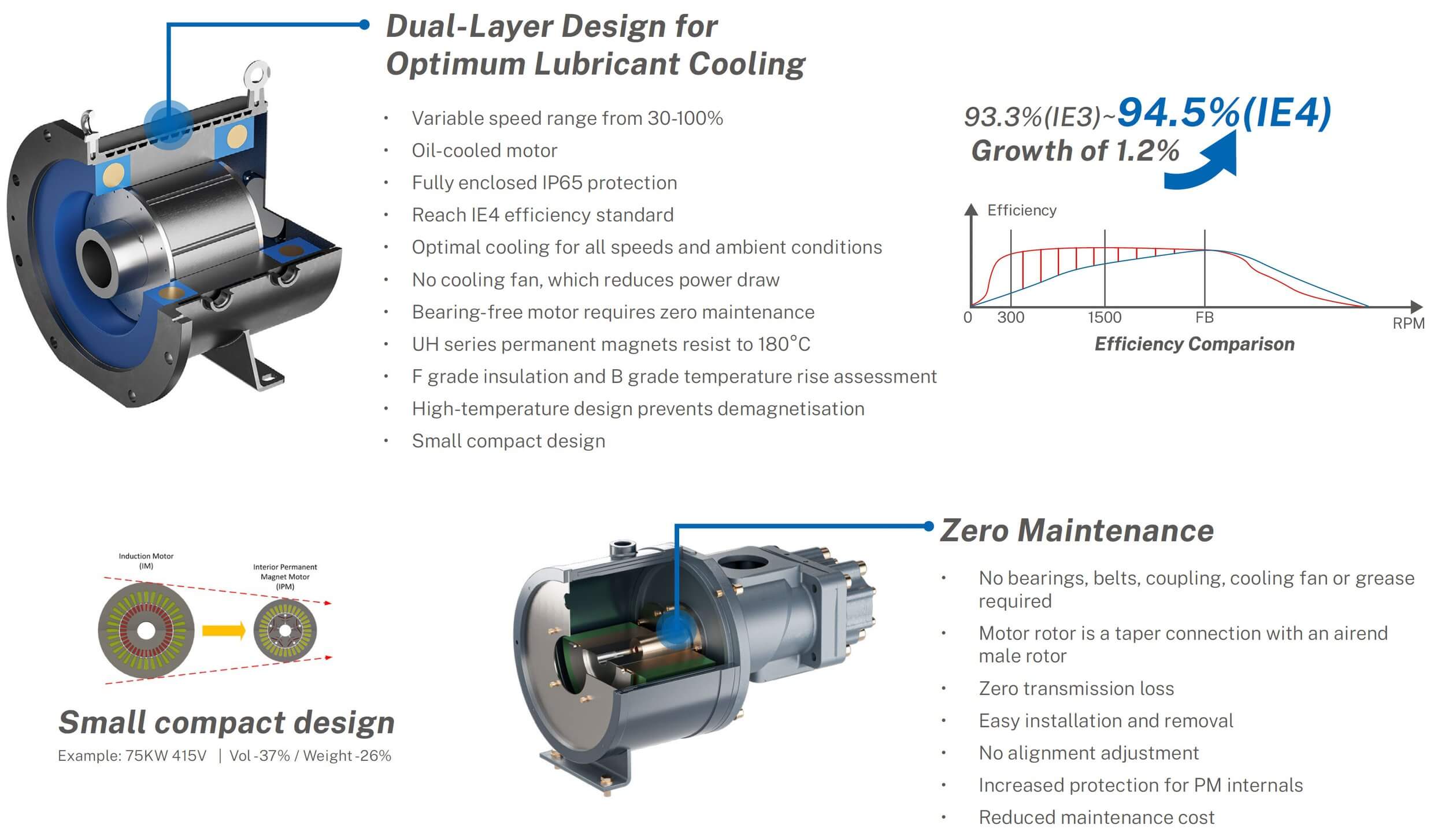

SUPER PREMIUM EFFICIENCY EPM MOTOR (IE4 EQUIVALENT)

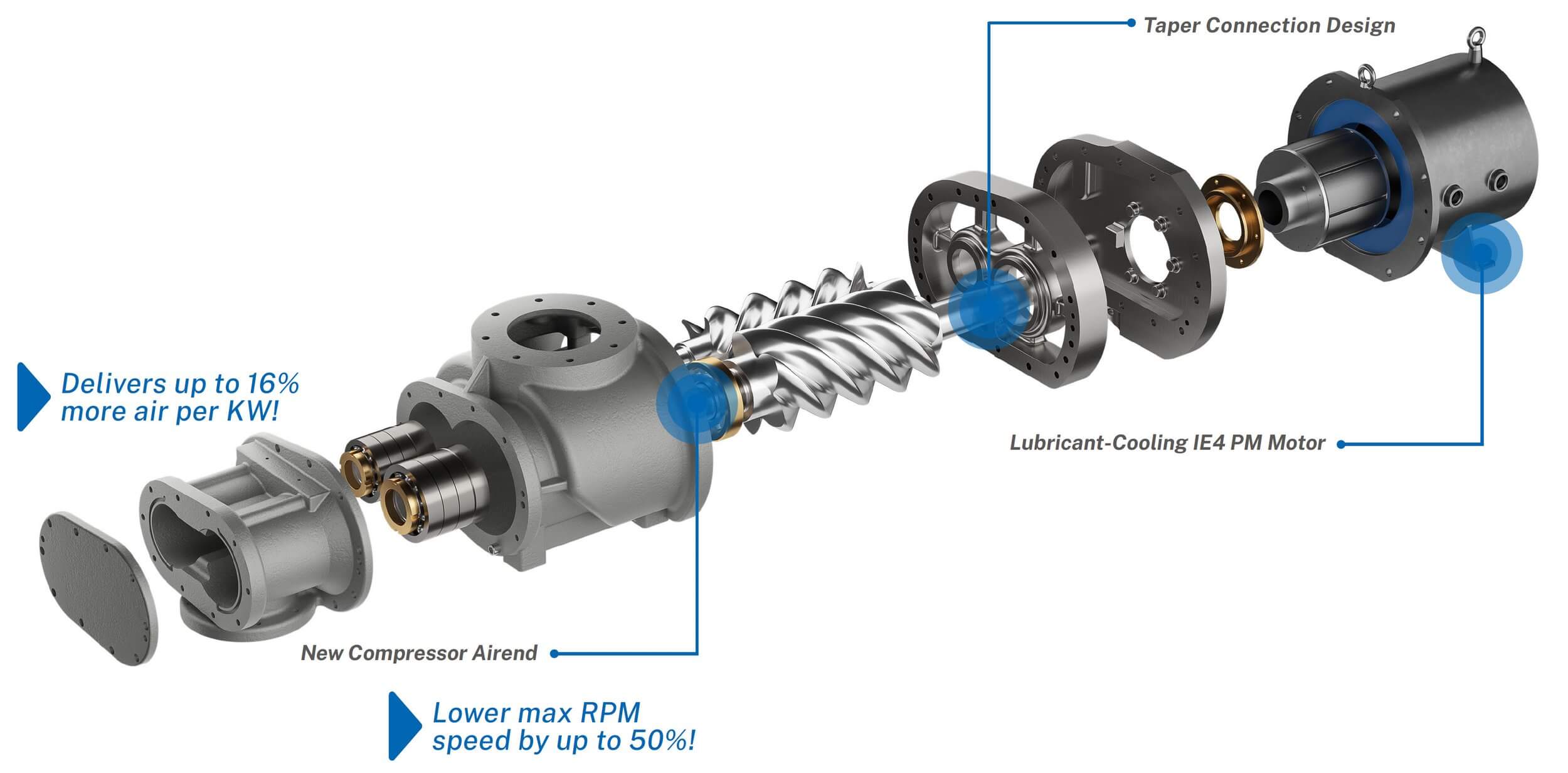

INNOVATIVE SCREW COMPRESSOR TECHNOLOGIES

- State-of-the-art airend improves efficiency as much as 16%

- 30 – 50% lower max RPM speeds (1500-2200RPM) – Standard is 3000RPM

- Increased rotor sizes by 50% for lower rotational speed

- Japanese research, development and design

- High-efficiency airend profile

- Isothermal compression

- Multi-point atomisation injection technology

- Flow-optimised for impressive performance

- Reduced pressure losses

- Optimised in and outlet portals

- Original world-famous bearing brands from SKF, TIMKEN and FAG.

- European made Teflon oil seals

- Designed for 20 years of reliable operation

INNOVATIVE MOTOR LIQUID COOLING TECHNOLOGY

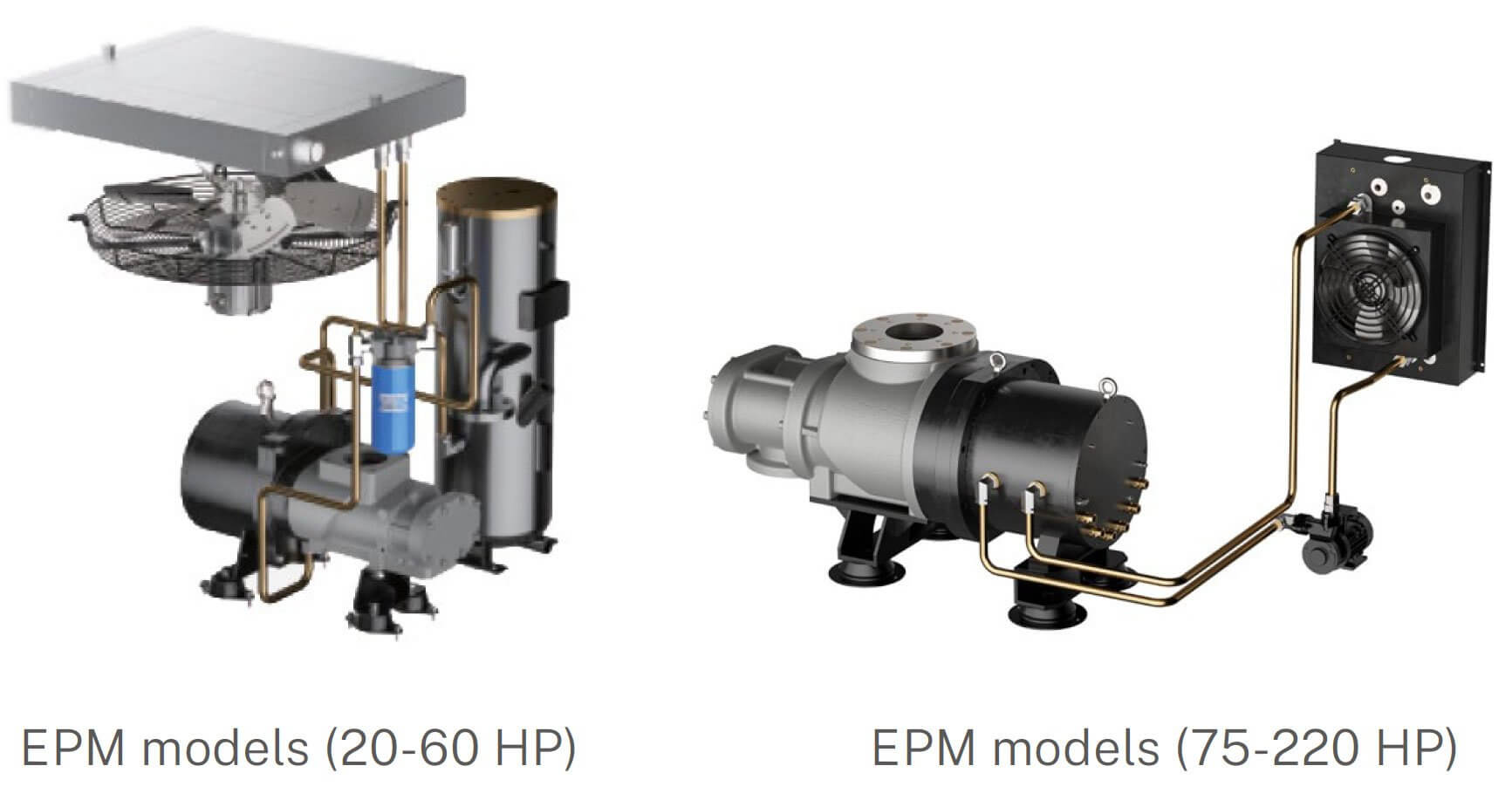

- Compressor oil cooling system for PM motor (20-60HP)

- Independent closed-loop coolant cooling system (75-220HP)

- Independent cooler, pump and fan cooling (75-220HP)

SCR EPM2 KEY FEATURES

1. PERMANENT MAGNET (PM) MOTOR

- Exceeds IE4 standards

- Lubricant-cooled motor

- VSD: variable speed drive

- IP65 protection

2. NEW COMPRESSOR AIREND

- 16% more efficient

- Oversized airend

- Lower maximum rotational speed

- R&D in Japan

- Designed to give many years of reliable operation

3. INLET FILTER

- Nanoscale heavy duty

- Filtration accuracy up to 99.9%

- Dust particles below 0.3 micron

- Pressure drop indicator

- Extends the service life of the lubricating oil and oil filter

4. COOLING FAN

- VSD control

- Compact

- Low noise level

- High capacity for optimised cooling

- Low power consumption

5. CLASSIC COOLER DESIGN

- Separate oil/air cooler

- Easy access for maintenance

- Anti-corrosion painted surface

- 30% oversized cooler design

6. INNOVATIVE INOVANCE INVERTER

- CE/UL/CUL certification

- Wide voltage design

- Meets C3 and C3 EMC requirements

- Built-in DC reactor

- Independent cooling air duct design

- Robust enclosure for trouble-free operation even in the harshest conditions

7. SCR 9000 TOUCH CONTROLLER

- Seven-inch full-colour touch screen

- Real-time operation/maintenance/alarm information

- Full graphical flow diagram

- Operation record/chart display

- Weekly and daily scheduling, service history and planning

- RS485 interface, MODBUS RTU Protocol+

8. INLET VALVE

- Optimises the inlet flow of the airend

- No blowdown losses

- Full aluminium maintenance-free design

- High vacuum degree: 700mmhg

- Large suction area

- Low load energy consumption in unloaded operation

- Fluoro rubber for improved valve seal

9. OIL FILTER

- High-efficiency oil filter removes contaminants from the oil

- Oil particles can be controlled at 0.1 micron

- Ensures a smooth and well-lubricated oil system

10. GAS TANK & BUILT-IN SEPARATION SYSTEM

- AS1210 designed and certified

- Oversized air and oil tank improves the cyclone effect maximising the separation process

- The high-efficiency oil separator ensures that the oil carryover is less than 3ppm

- Systems pressure loss: less than 0.02mpa

- The rotating oil tank lid makes maintenance convenient and straightforward, reducing maintenance downtime

11. ELECTRICAL CONTROL CABINET

Siemens core electrical components further enhance reliability

12. ALL STEEL INTERNAL PIPE SYSTEM

- All steel internal pipework and compression joints prevent the leakage and premature ageing often seen with flexible pipes

- Reduced air flow friction

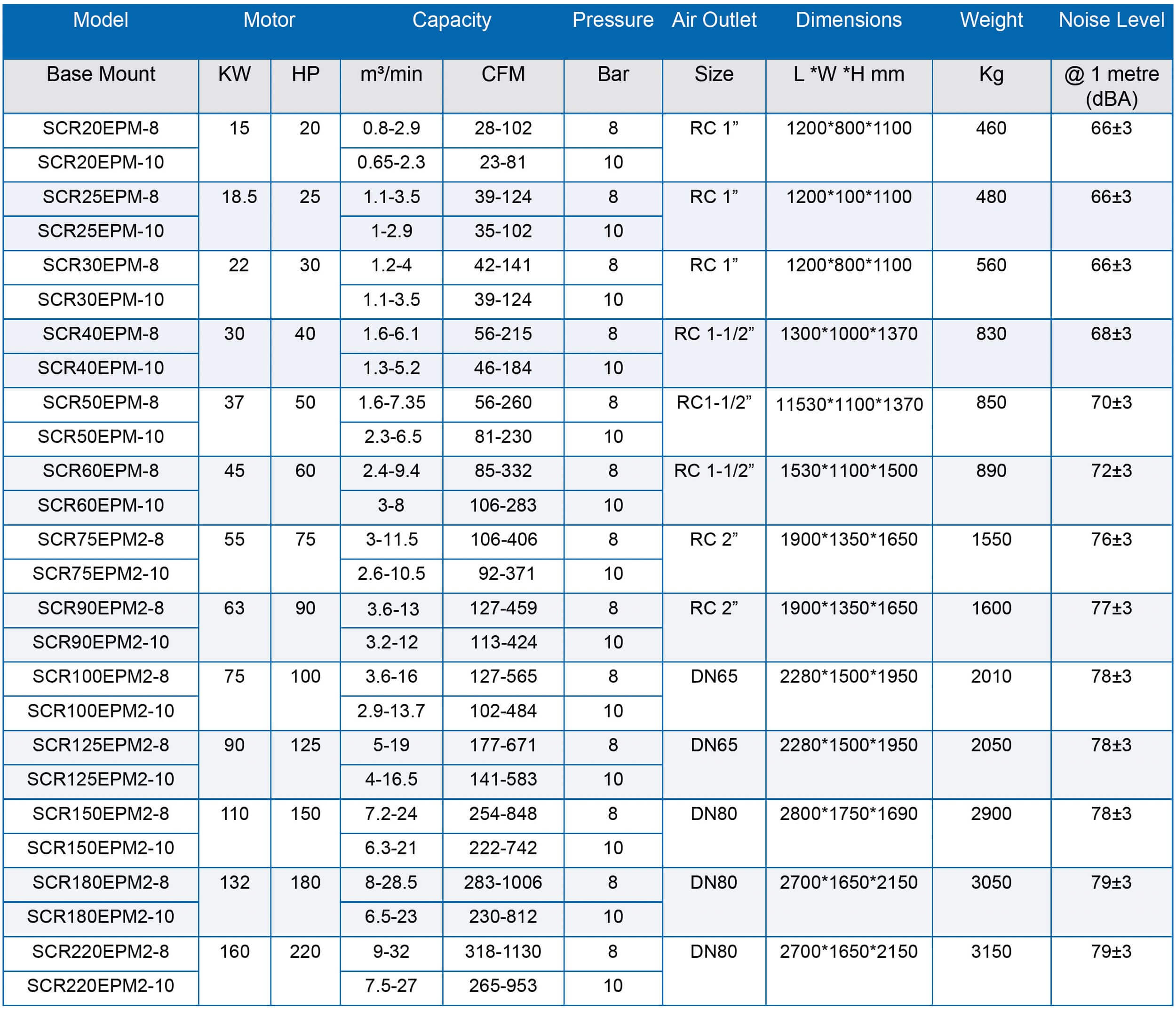

SPECIFICATION

Warranty

Standard 2-year warranty – covers the complete compressor (terms and conditions apply)

1300 183 355

1300 183 355  sales@westairps.com

sales@westairps.com