Rotary Screw Direct Drive Compressor

RELIABLE / ROBUST / PROVEN

10 years of operation in Australia’s harshest conditions

As the sole distributor of SCR Compressors in Australia, Westair are pleased to introduce their range of Direct Drive Rotary Screw Compressors. The SCR Direct Drive range are of robust design with low speed, oversized airends and uncomplicated 1:1 ratio drive, resulting in strong, reliable and long life machines.

FEATURES:

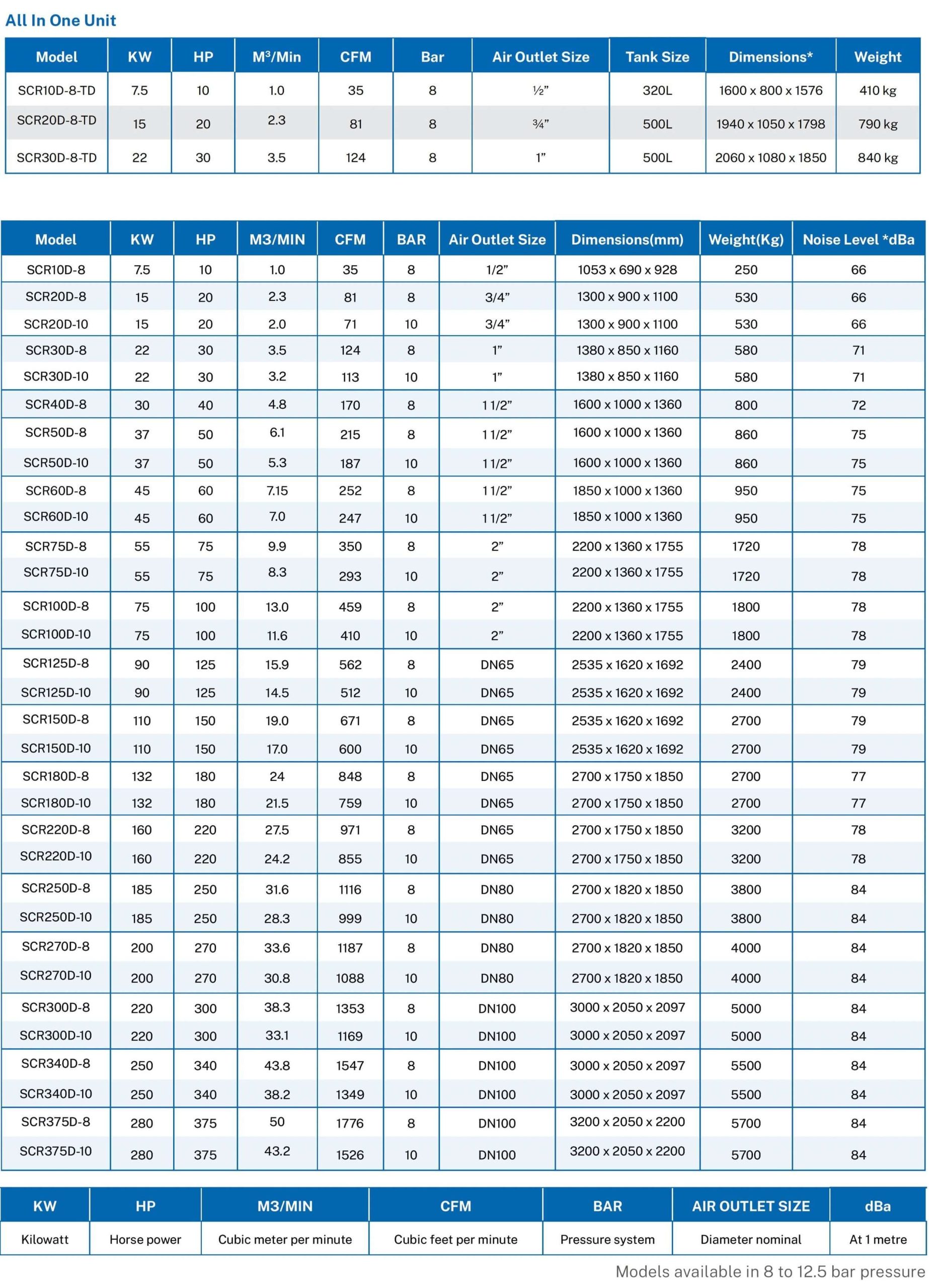

- 7.5 kW to 280 kW units available

- Pressure ranging from 8 bar to 12.5 bar

- Intelligent Micro Controller for more energy efficient control

- Major components of European design and manufacture

- Long term warranty on complete packages

- Maintenance friendly with large removable and lockable panels

DIRECT DRIVE ADVANTAGES

With many advantages, the SCR Direct Drive compressor would be an excellent choice in value. SCR use oversized airends and a 1:1 ratio drive. The 1:1 ratio means the motor is directly coupled to the airend via a maintenance free coupling that eliminates transmission loss and reduces noise dramatically. Compared to other compressors using belt drive or small high speed gear driven airends, the SCR Direct Drive delivers outstanding performance and significant energy savings.

- Designed for harsh environments

- Lower power consumption

- Energy efficient

- Low noise

- Reduces maintenance cost and down time

- No power transmission loss

- Eliminates the use of belts

MINING FEATURES AVAILABLE

- Weather proof

- Stainless steel door, frame and base option available for erosive environments

- Heavy duty air filtration

- Electrical cabinet upgrades to suit mine site specifications

- Industrial external filter mats

- 24v control voltage

- Ingress protection (IP) upgrade on drive and fan motor

INTELLIGENT MICRO CONTROLLER

The intelligent patented micro plc controller is user-friendly. It has signals for pressure, temperature and current, which monitor the running of the compressor. With a secured code, setting up or changing parameters in the system can be easily achieved using the buttons on the display.

The display has readings for

- Running amps

- Service intervals

- Pressure

- Temperature

- Current

- On load and off load hours

- Reverse anti-rotation alarm

- Date and time

- Fault history

- Plus up to 13 different monitoring alarms

Controller options:

- Remote stop/start

- Power outage start up

- Master slave operation

- RS485 Connection

- Modbus RTU

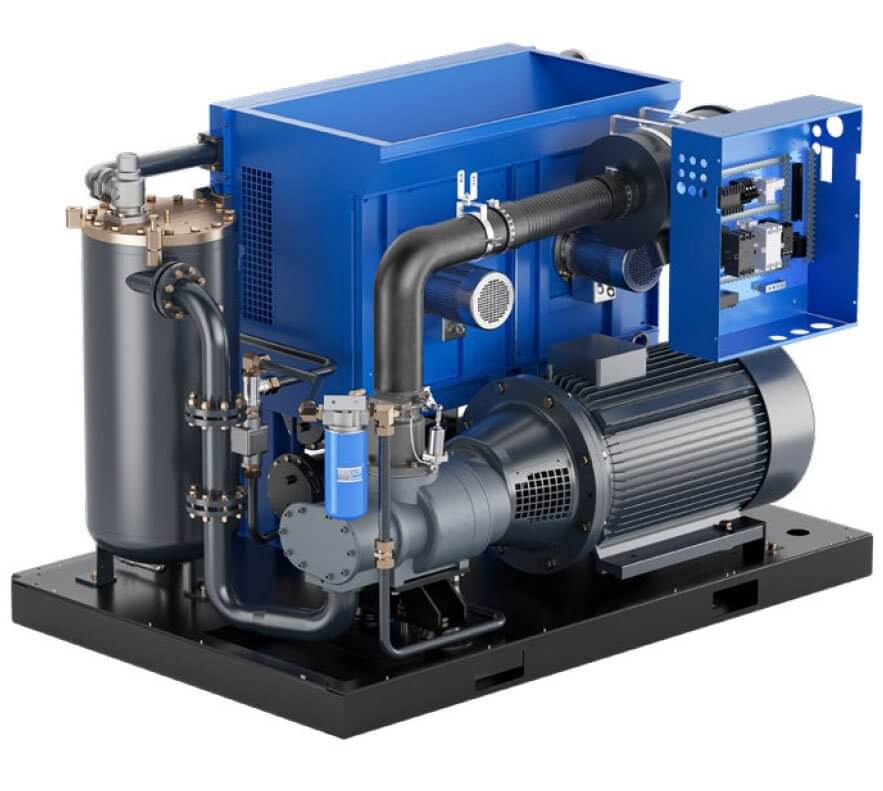

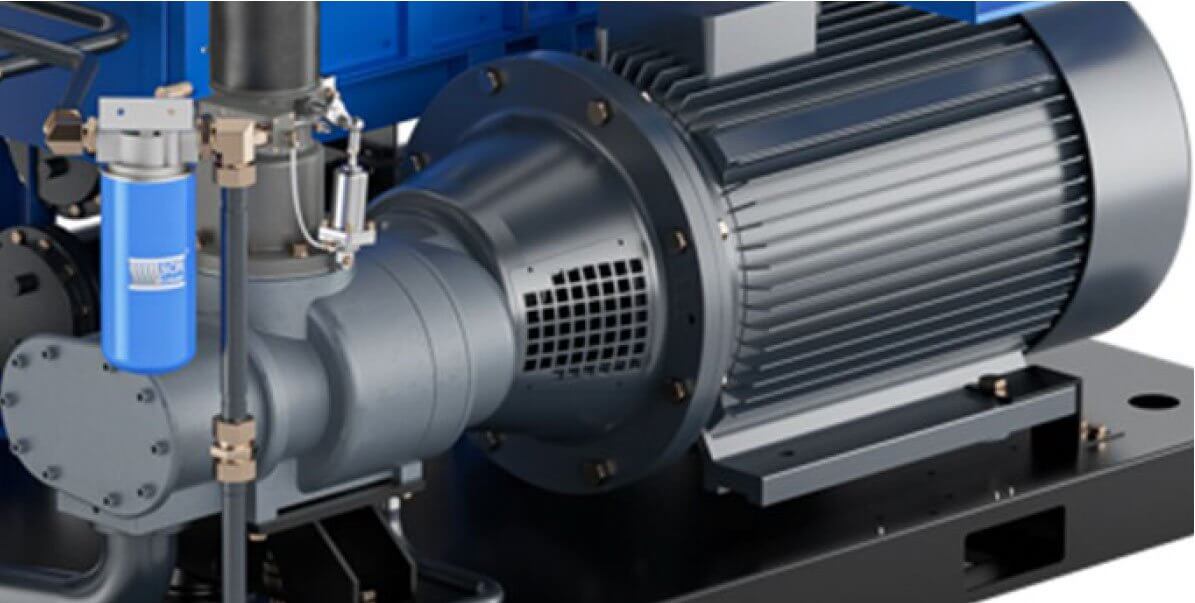

QUALITY EUROPEAN COMPONENTS MOTOR

All our SCR Direct Drive compressors are fitted with MEPS 2 compliant industrial motors. The SKF front and back bearings have greasing nipples to ensure a long service life.

AIREND

SCR airends are fitted with patented German made rotors, SKF bearings and European made Teflon oil seals. These high quality components ensure high efficiency, long running and low noise/vibration of the airend.

ELECTRICAL COMPONENTS

Siemens is the main core of the electrical components within the starter. This ensures the long term stable operation of the compressor.

TRANSMISSION

KTR German made coupling connects the motor to the airend with a 1:1 ratio. WVIF high efficiency shock pads are used on the motor and airend to lower the torque impact and vibration.

OIL SEPARATOR

Our oversized oil separator filters ensure a longer life and a sustained clean air delivery of less than 3ppm oil content, resulting in a differential low pressure loss of less than 0.02Mpa.

SUCTION VALVE

The SCR suction valve is a high quality key component which brings the compressor on and off load and has an expected service life of over 2 million cycles. The longevity and reliability of this valve is due to no gap needing to be completely sealed, therefore eliminating problems such as deteriorating cup seals and diaphragms.

THERMAL VALVE

Renowned Hoerbiger thermal valves are used in our units. The thermal valve opens and shuts many times during operation, to help the compressor maintain its optimum temperature.

COOLER

Our large oversized coolers have been designed to keep the compressor cooler in Australia’s harsh summers.

SOLENOID AND PRESSURE CONTROL

European solenoid valves and sensors are used as the main pneumatic and sensor control components.

SEAMLESS STEEL PIPES

Made from seamless steel, the oil pipes are connected together with high quality compression fittings. This pipe system eliminates ageing and oil leaks.

AIR INTAKE FILTRATION

The global Donaldson brand is just one of the high efficiency, low loss imported air filtration used on all our SCR compressors. Intake air quality is a key to compressor reliability. If the machine can breathe clean air it will reduce running costs and extend the life of the machine.

SPECIFICATION

Warranty

Standard 2-year warranty – covers the complete compressor (terms and conditions apply)

1300 183 355

1300 183 355  sales@westairps.com

sales@westairps.com